Stampa

Buckshot Swager Machine

Semi Automatic

High Capacity

Special Design

Key-Turn Project

2 Years Warranty

Robust Body

Technically the lead ball starting from 4.00 mm. diameter called as buckshot. The most popular buckshot diameters are: 4.50mm. 6.00mm. 6.40mm. 7.20mm. 8.00mm. and 8.60mm. Buckshot can not be produced by bleimeister method.

The most popular and reliable method to produce buckshot is swaging. Leadwire is used as the initial material and molds form the round lead ball. Because there is no melted lead the worker safety and human health issues are better.

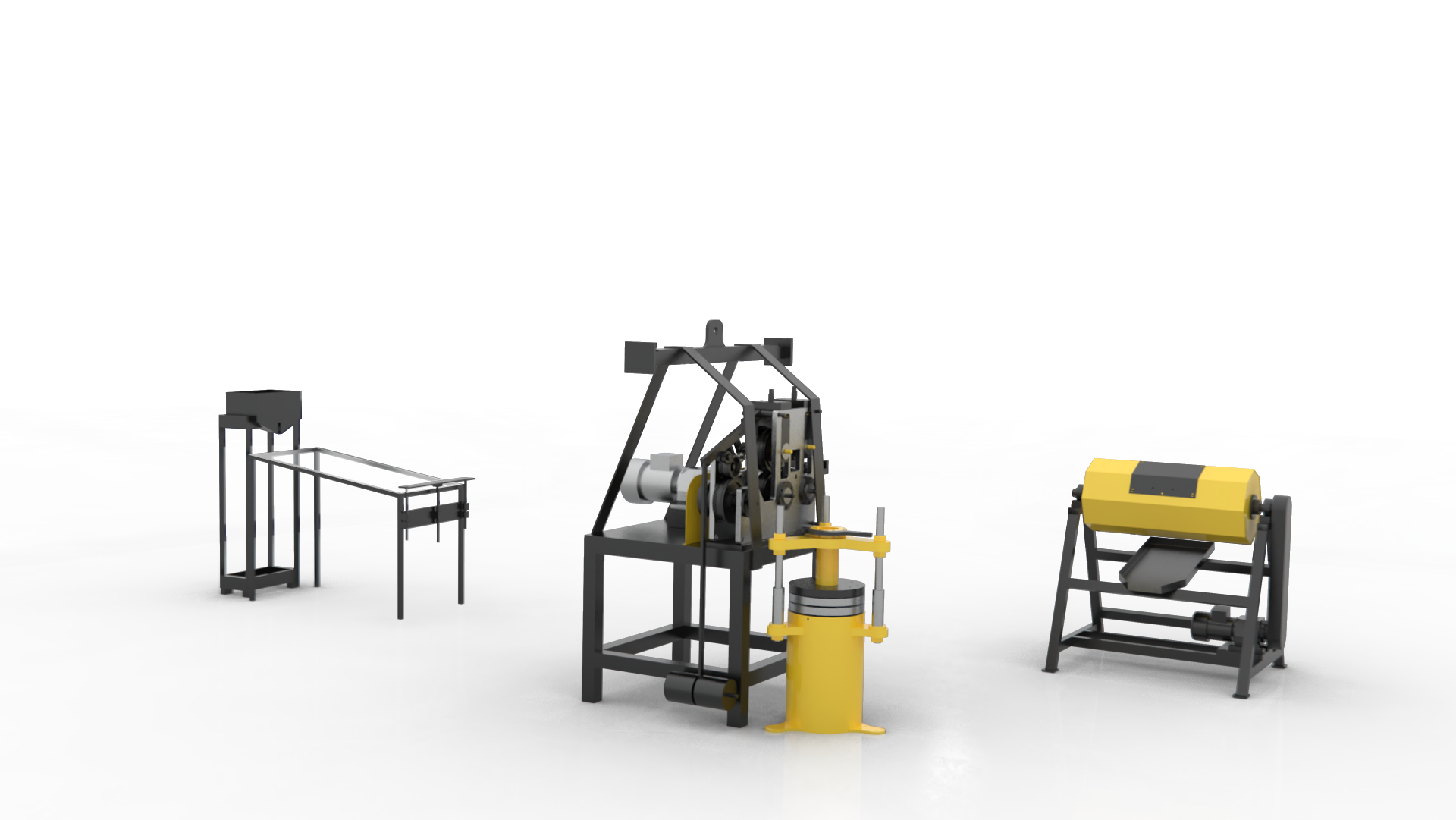

With our swaging tecnique the leadwire gets the round shape. With the tumbler the round shapes get smooth. One additional tumbler makes the graphite coating. Finally the mirror makes the selection.

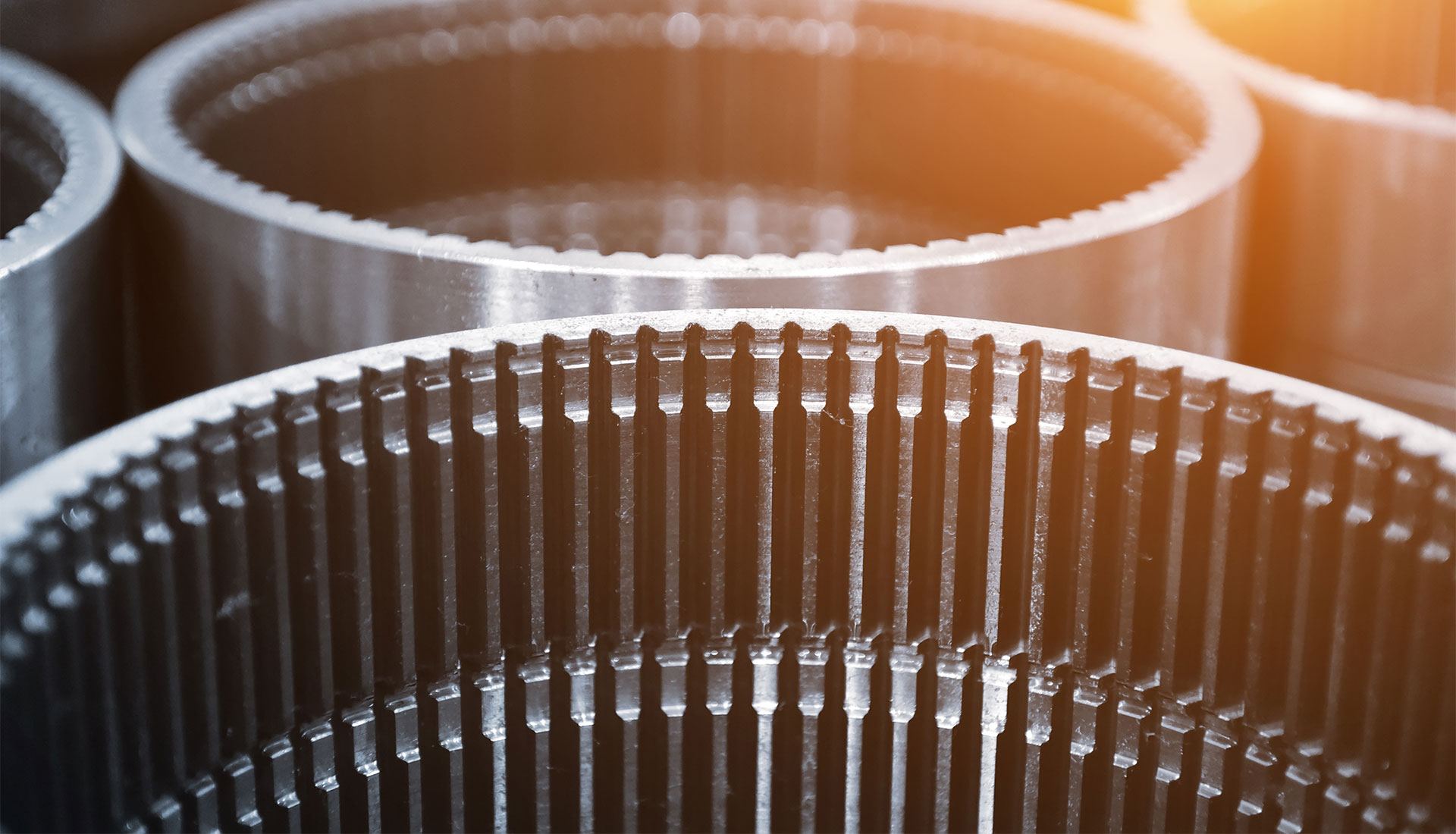

The most crucial part of all this process is the molding. As the molding like other crucial parts are made inside our factory we are able to control all quality related points. We are able to offer any diameter of buckshot for the producers.

| Semi Automatic | : | From leadwire to buckshot semi automatic manufacturing. |

| High Capacity | : | High capacity buckshot production. |

| Special Design | : | Special design molding system. |

| Key-Turn Project | : | Ready-to-use production system. |

| 2 Years Warranty | : | 2 years full warranty 10 years service guarantee. |

| Robust Body | : | Quality iron and stainless steel body. |